What is a Digital Twin?

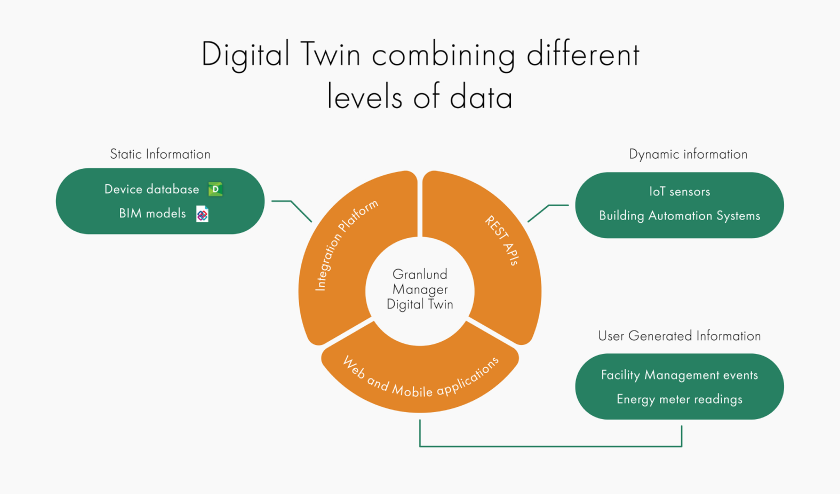

The Digital Twin shows the 3D model of a property in an easily understandable format. It reads static data from BIM models and dynamic data from building automation and management systems, IoT sensors and other data sources.

Synchronised data sources

The Digital Twin is a tool for managing property maintenance processes and information. It collects all the important information for maintenance from various sources, such as IFC data models of design and construction data, IoT and automation systems, as well as end users.

Synchronised property information is always up-to-date and can be utilised for example in future development projects.

Visualise conditions & performance

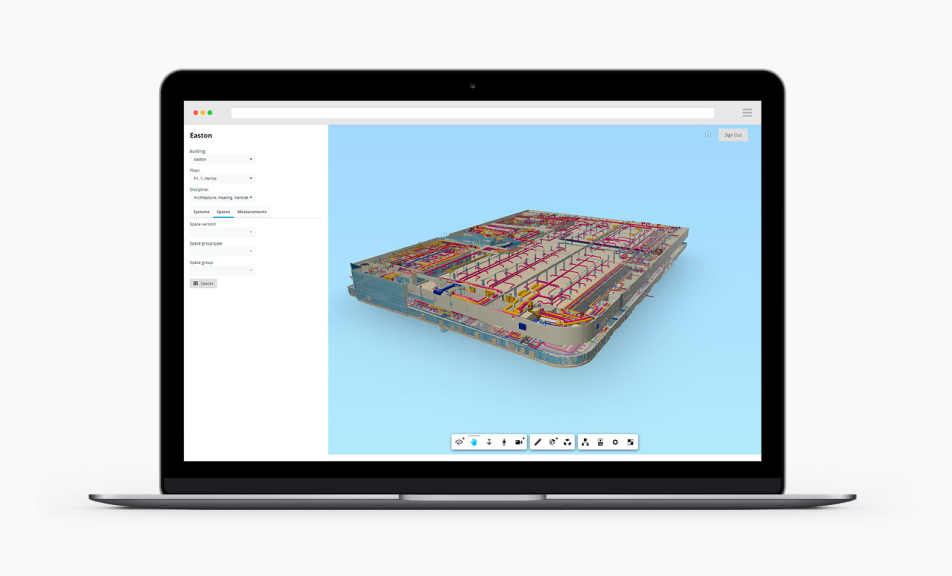

The illustrative and user-friendly Digital Twin raises the usability of the Granlund Manager software to a new level. It ensures that the required information collected during design and construction phases is available to users in a visual format. This improves information availability and usability for the property owner, service providers and end-users.

The visual interface provides property managers with a clear overall picture of the property maintenance process, indoor conditions and technical performance. It enables condition monitoring on a building, floor and spatial level. Additionally, it can be used for fault diagnostics by helping detect root causes.

Digital Twin in action

The Granlund Manager Digital Twin was piloted at the National Museum of Finland. Take a look how the virtual building looks like in real life.

How are digital twins created?

Digital twin is a virtual duplicate of a building created by enriching the geometric or graphical data with support from building automation systems, sensors and IoT components.

See also

Smoother maintenance

Take control of building asset data and any related activities for smarter maintenance planning

Increased energy efficiency

Reduce costs and increase property sustainability through operability managment and energy opitmisation

Dynamic reporting

A broad set of reporting capabilities for maintenance processes and energy consumption